Serial Robots review, advantages, disadvantages and what can serial robots do?

Serial robots can pick and place objects, and sort items on conveyor belts, They can handle and manipulate objects at high speeds, They can be equipped with welding torches or painting tools, allowing them to automate these tasks in a controlled and consistent manner.

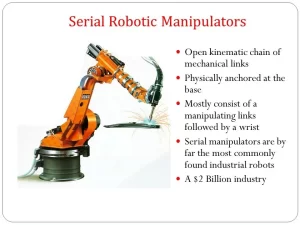

Serial robots

Serial robots, also known as articulated robots, are the most common type of industrial robot. They have a linked arm structure, where each joint adds another degree of freedom (DOF) to the robot’s movement, and extends the reach of the robot. They resemble a human arm, with joints connected in a sequence.

Serial robots, with their many joints and reach, are capable of a wide range of tasks. Their versatility and ability to be programmed for specific tasks make them a valuable tool in many industries, from manufacturing to healthcare and agriculture.

Serial robots offer a good balance of flexibility, programmability, and workspace. They are a popular choice for various industrial and non-industrial applications due to their versatility and ease of use. However, their payload limitations, footprint, accuracy considerations, and complexity and potential for singularities need to be considered when choosing the right robot for a specific task.

What can Serial robots do?

Their precise movements and dexterity make them ideal for intricate assembly tasks in electronics manufacturing, such as placing delicate components on circuit boards. A classic application is precise assembly tasks in factories. They can pick up components, fit them together, and perform actions like screwing or welding with high accuracy.

This is common in electronics and automotive manufacturing. They excel in precise assembly tasks, like putting together electronic components or car parts. Their dexterity allows for handling small parts and maneuvering them into place with high accuracy. Their versatility makes them a valuable tool in many industries.

They can pick and place objects, sort items on conveyor belts, or load and unload materials in factories. Their reach and dexterity allow them to handle objects from different angles and positions. Packaging products are well-suited for serial robots. Their programmability allows for the efficient handling of various materials.

Their ability to reach different angles and their controlled movements allow them to perform tasks like painting car parts or welding seams on complex structures. Serial robots can be equipped with welding torches or painting tools, allowing them to automate these tasks in a controlled and consistent manner.

Their controlled movements make them ideal for applying paint or other coatings on products with complex shapes, ensuring even coverage. Many industrial welding processes rely on serial robots for precise torch control. They can weld different parts together with high repeatability.

Serial robots can handle and manipulate objects at high speeds, making them suitable for packaging lines where they can place items in boxes or arrange them on pallets. They can be programmed to load and unload materials from CNC machines, lathes, or other automated equipment.

Some serial robots can handle tools for drilling, grinding, or polishing tasks. Their ability to follow specific paths allows for precise machining and finishing of workpieces. With proper grippers or tools attached, they can be used for selective disassembly tasks or controlled demolition in controlled environments.

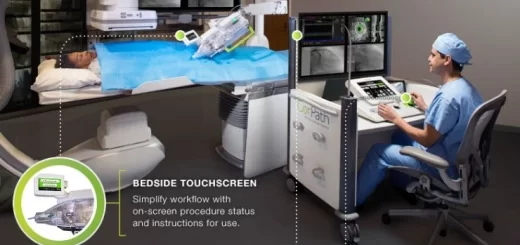

Telemanipulated surgical robots are a type of serial robot that allows surgeons to perform minimally invasive procedures with greater precision and control. In research labs, these robots can handle delicate tasks like sample preparation, analysis, or material testing with high precision and repeatability. Their precision allows them to conduct experiments, or perform delicate procedures in scientific research settings.

Serial robots are equipped with cameras and sensors, serial robots can be used for visual inspection of products or quality control checks by measuring dimensions or detecting defects. Their precise movements and potential for integration with vision systems make them suitable for tasks like inspecting products for defects or ensuring quality control.

Serial Robots advantages

Serial robots can have 6 or more DOF, allowing for a vast range of motion and flexibility. This makes them suitable for complex tasks requiring dexterity and manipulation, like painting, assembly, and welding. Serial robots can have a wide range of motion (DoF) thanks to their multiple joints. This versatility allows them to perform complex tasks and reach various positions within their workspace.

The serial structure simplifies the mathematical calculations needed for robot movement (kinematics). This makes them easier to program and control compared to parallel robots. Due to their rotational joints, serial robots can reach a larger workspace and access hard-to-reach areas compared to other designs. This is beneficial in applications like painting or material handling.

Their versatility makes them suitable for various tasks, from delicate assembly operations in electronics manufacturing to welding and painting in automotive industries. Due to their rotational joints, serial robots can reach a larger workspace compared to other designs. The multi-jointed arm allows for a high degree of dexterity, enabling them to handle objects with intricate shapes and perform precise manipulations.

Their high DoF and ease of programming make serial robots adaptable to various tasks. They can be equipped with different end-of-arm tooling (grippers, sprayers) to handle diverse objects and applications. They can be used in assembly lines, painting, welding, material handling, and many other applications.

Serial Robots disadvantages

The linked structure can limit the weight a serial robot can carry compared to some parallel robots, because the force exerted by the motor at each joint needs to be transferred through subsequent joints, potentially reducing overall payload capacity. As the arm extends, the moment arm (distance from the joint to the center of mass) increases, reducing the force the joints can exert.

The extended arm structure can occupy more space compared to some parallel robots. This might be a limitation in applications with tight workspace constraints. The base and arm structure of a serial robot can take up more space compared to some other robot designs. As the number of DOF increases, the robot’s arm can become bulkier, potentially restricting its reach in certain configurations.

The linked joints can introduce some flex in the robot‘s arm, potentially affecting precision in high-speed or high-force applications. The multi-joint design can make serial robots more complex to design and maintain compared to simpler robots.

In some configurations, a serial robot’s joints might reach a singularity, where even small motor movements cause unpredictable and large end-effector movements. Careful programming is needed to avoid singularities.

The accuracy of a serial robot can be affected by factors like joint wear, gear backlash (looseness in the joints), joint deflection, and flexing of the arm structure, especially when the arm is fully extended. Depending on the complexity, serial robots can be more expensive than some simpler robot designs.

You can subscribe to Science Online on YouTube from this link: Science Online

You can download Science Online application on Google Play from this link: Science Online Apps on Google Play

Collaborative robot arm (cobot robots) applications, uses, advantages and disadvantages

Automation in manufacturing uses, advantages and disadvantages

Industrial robot (Auto industry) uses, advantages and disadvantages