Thermoplastics properties, types, uses, advantages and disadvantages

Thermoplastics can be differentiated from the thermoset materials, They are the organic materials that melt when they are heated, They can be remelted back into the liquid, They are formed when they are in the melted or viscous phase, They are heated, formed and cooled in their final shape, whereas the thermoset plastics remain in the permanent solid state.

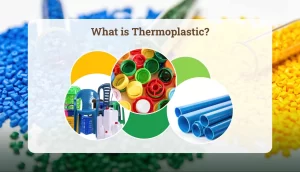

Thermoplastics

Some types of thermoplastics are expensive, strong and used in place of metal, while the others are used in common everyday products, They are easy to mold and shape when they are hot, They can turn to liquid at high temperatures, When they are cooled, They turn into hard and solid plastic, The keyboards and compact disc cases are made of the thermoplastics.

The most popular methods of processing thermoplastics are injection molding, extrusion, and thermoforming, The thermoplastics can be like rubber or as strong as aluminum depending on their chemistry, They are lightweight, Some thermoplastic materials can withstand temperature extremes up to 600 F, while the others retain their properties at -100 F.

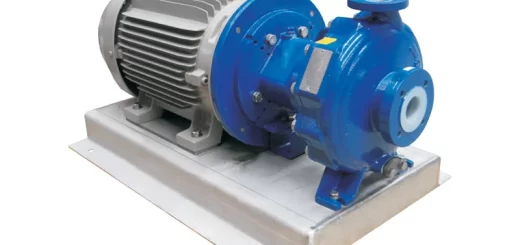

Some thermoplastic materials have no known solvents at room temperature, The thermoplastic composites can be made to be electrically conductive with the addition of carbon or metal fibers, The combination of lightweight, high strength and low processing costs make the thermoplastics well suited to many applications, They are used as thermal insulators and electrical insulators.

Two types of thermoplastics are high-temperature thermoplastics and engineering thermoplastics. Examples of high-temperature thermoplastics include popular materials such as polypropylene and PVC. They are commonly used for pipes, bottles, and plastic containers.

Engineering thermoplastics are typically flame-retardant, and they can withstand temperatures of up to 100 °C. Engineering plastics cost much more to produce than these popular materials. They contain materials such as nylons and polyesters.

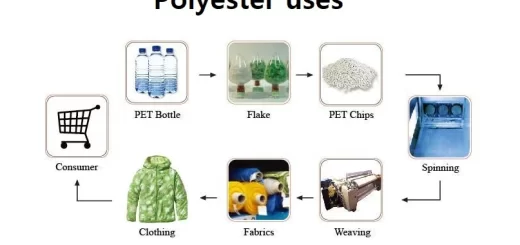

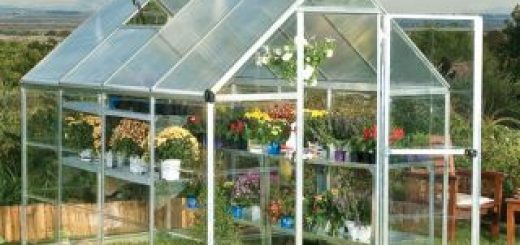

One type of thermoplastic is called polyester resin, It is used for car bodies and garden furniture, Another type of thermoplastics is polymethyl methacrylate, It is used for lenses and windows.

Thermoplastics advantages

Thermoplastics are energy efficient both in their manufacture and processing, Thermoplastic components can be made in very high volume with high precision and low cost, They can replace the metals with considerable weight savings, and proper care is taken in the design, Most thermoplastics have better properties than the metals and they can tolerate larger deflections than the metals without deforming.

The thermoplastics can be remolded and recycled without negatively affecting the material’s physical properties, They can soften when they are heated and they become more fluid as additional heat is applied. The curing process is completely reversible because no chemical bonding takes place.

Thermoplastic materials offer many performance benefits. Most thermoplastic materials offer high strength, shrink-resistance, and easy bendability. Depending on the resin, they are used in low-stress applications such as plastic bags or high-stress mechanical parts.

Thermoplastic materials have high strength. They are lightweight, and they come with relatively low processing costs. You can manufacture thermoplastic components easily in high volumes with high precision. The engineers use thermoplastics instead of metals because of their much lighter weight.

Thermoplastic materials are highly recyclable. They offer aesthetically superior finishes, they have High-impact resistance, they contain remolding/reshaping capabilities, they offer chemical resistance, they have a hard crystalline or rubbery surface option, and they have Eco-friendly manufacturing.

The thermoplastics can soften or melt when they are heated and returning to solid when they are cooled, The process is repeatable and it does not change the chemical nature of the polymer, Heating provides the thermal energy to allow the long polymer chains to move freely past one another and take on new shapes, Cooling reduces molecular motion to the level where the chains no longer move freely.

Thermoplastics, with the exception of polyester and polyimide film, have only recently gained popularity, particularly for microelectronic structures in recent times, Advanced thermoplastics can now provide high melting points and exceptional stability early generation polymers could not offer.

Thermoplastics disadvantages

Many thermoplastic materials, especially composites, tend to fracture rather than deform under high-stress levels, They suffer from creep where the thermoplastics materials relax or weaken when they are exposed to long-term loading.

The primary drawback of using thermoplastics instead of the materials such as metal is that the thermoplastics can melt, Some types of low-quality thermoplastics melt, and some thermoplastics degrade when they’re exposed to direct sunlight or ultraviolet light levels for extended times.

Thermoplastics are more expensive than thermoset materials, and they can melt if heated. Many materials have poor resistance to hydrocarbons, organic solvents, and highly polar solvents, but others have excellent resistance to these materials.

Is thermoplastic bad for the environment?

Thermoplastics can be bad for the environment, depending on how they are produced, used, and disposed of. Thermoplastics aren’t inherently “bad,” but their environmental impact depends heavily on:

- How they are used (e.g., single-use vs. durable goods),

- How they are disposed of (landfill, recycling, or litter),

- And whether cleaner alternatives or bioplastics are viable substitutes.

Negative Environmental Impacts

- Most thermoplastics (like polyethylene, polypropylene, and PVC) are not biodegradable, meaning they can persist in the environment for hundreds of years.

- As thermoplastics degrade (especially in oceans and soil), they break down into microplastics, which can be harmful to wildlife and potentially enter the food chain.

- Most thermoplastics are made from petroleum-based materials, contributing to fossil fuel depletion and greenhouse gas emissions during production.

- Some thermoplastics release harmful chemicals during manufacturing or when burned (e.g., PVC can release dioxins), which can be hazardous to both humans and ecosystems.

Potential Environmental Benefits

- Unlike thermosets, thermoplastics can be melted and remolded, which makes them recyclable — but only if they are properly collected and sorted.

- In some cases, their long lifespan can reduce the need for frequent replacement, which could be environmentally favorable compared to disposable alternatives.

- In packaging and transportation, using thermoplastics can reduce weight and thus fuel usage in logistics.

You can subscribe to Science Online on YouTube from this link: Science Online