The hardness of materials and life applications on it

Hardness of materials

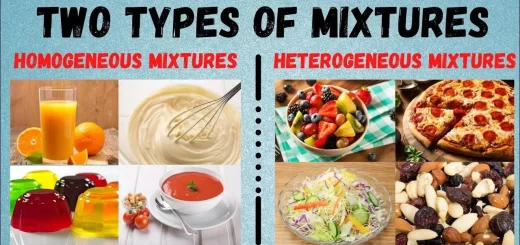

Some solid substances are soft at room temperature such as the rubber, and some solid substances need heat to become soft and easy to be shaped such as the metals, and some solid substances can’t be soften by heating such as coal and sulphur.

The hardness of materials has been assessed by the materials resistance of cutting, scratching or bending, and it is measured by the resistance which a smooth surface offers to abrasion.

The degree of hardness is determined by observing the comparative ease or difficulty in which one mineral is scratched by another, Hardness is the property of a material that enables it to resist the plastic deformation by penetration.

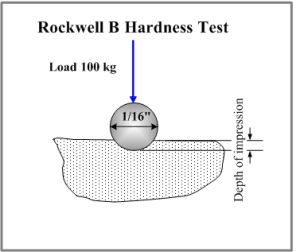

Hardness is the resistance of a material to deformation, indentation or penetration by drilling, abrasion, impact or scratching, Hardness is measured by hardness tests such as Brinell, Rockwell, Knoop or Vickers tests, and there is no standard hardness scale.

The hardness of alloy is the diameter of the dent an alloy measured when 1 kg of weight is dropped onto it, The smaller the diameter of the dent formed on the alloy, the harder the alloy.

The hardness tests serve an important need in the industry, these tests are based on experiments and observation, They are able to detect certain differences between the materials.

The importance of hardness testing has to do with the relationship between the hardness and other properties of the material, and the hardness test is preferred because it is simple, easy and relatively nondestructive.

Life application of hardness

The screwdrivers are made of steel iron because it is very hard, and the rods used in building houses concrete are made of iron, not copper because the hardness of iron is more than that of copper.

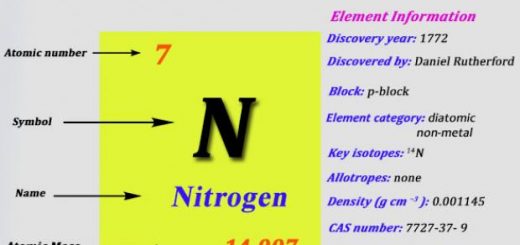

Matter, Properties & Kinds of molecules, Melting process & Vaporization process

Atomic structure of matter, Energy levels, Electronic distribution & chemical activity